The performance of steel components and steel structures in fire has been researched more extensively than any other building material.

Steel is a durable, non-combustible, fire-resistant material. When properly designed and constructed, a structural steel frame can retain its structural integrity for an extended period of time in the event of fire and prolonged exposure to elevated temperatures.

As the architect is the primary decision maker in configuring the initial form and function of the building or structure, decisions on the choice of structure must be well informed from the outset.

Fire test furnace for light gauge steel wall assemblies. Courtesy Queensland University of Technology.

The assessment of fire safety and the necessary measures to ensure life safety in the event of a fire require a rigorous process, irrespective of the type of building construction. The architect is integral to this process by setting the context for the building type – and gathering information on the performance of the fire-rated structure and the cost of providing that rating.

The cost of a fire-rated solution for steel structures is highly dependent on the approach taken to assess the required fire performance. The National Construction Code (NCC) mandates well-defined performance requirements for structures exposed to fire events, with the principle objective of ensuring life safety for the occupants of the building or structure and the first responders to the fire event. These performance requirements can be satisfied wholly or by a combination of two different approaches:

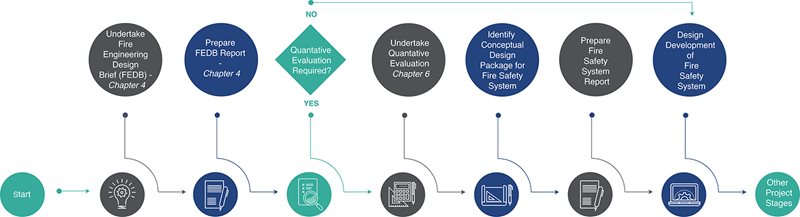

The ABCB 'Fire Engineering Guidelines' publication recommends the following conceptual design procedure for fire safety design. The architect should drive this early stage process towards a successful conclusion.

The Deemed-to-Satisfy approach via prescriptive requirements is, by its very nature, a generalised solution designed to be applicable to a majority of circumstances. It is typically a comparatively over-engineered and, hence, expensive solution given there is a reduced ability to match the solution to the exact project scenario.

A Performance Solution, on the other hand, has the capacity to provide a much better fit to the actual project scenario and is therefore a value-engineered solution with significant opportunity for enabling more cost-effective approaches.

The ASI strongly encourages exploration of performance-based approaches, termed fire-engineered design, for all but the most straightforward of steel structures. Explore our focus area on Steel and Fire for best-practice information on all aspects of fire performance of steel structures.

Intumescent coating on exposed steelwork. Courtesy International Paints.

The use of intumescent coatings and concrete-filled tubular members provides the greatest opportunity for architectural expression while retaining fire rating.

Significant innovation has occurred in recent years with coating technology for fire rating. So-called thin film intumescent coatings can facilitate architectural expression for steel that is fire rated.

Concrete-filled tubular members are becoming more common, especially as the main supporting columns for multi-storey buildings. Concrete filling allows the exterior steel to be largely devoid of fire protection as the concrete core can be designed to work with the steel to provide load-carrying capacity in the event of extreme fire load.