Multi-level buildings, principally in the form of office blocks, residential towers and (more recently) schools dot the skyline of our capital cities and large regional centres. Steel's role is critical – more than half of the steel produced worldwide goes into steel buildings and infrastructure.

Rapid urbanisation will increasingly drive the multi-level and mid-rise construction markets for steel solutions as a cost-effective response to the need to house our community and workforce in energy-efficient sustainable buildings.

.jpg?variant=HalfWidth)

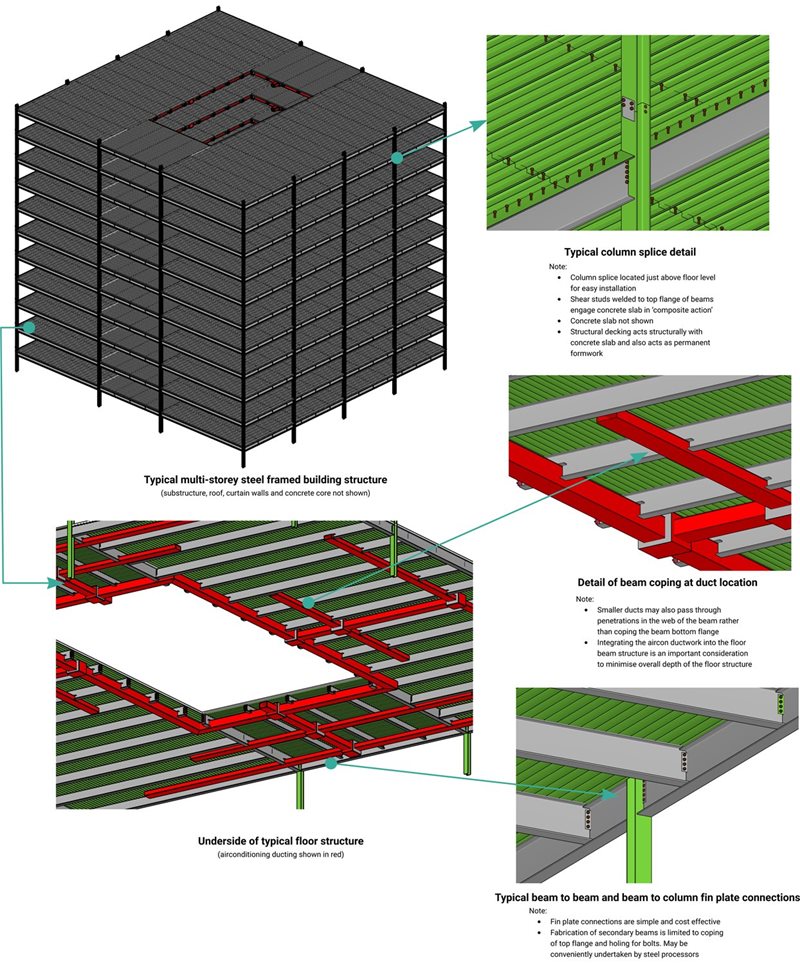

The configuration of multi-level buildings, with its basic principles of columns supporting floors and its system of structural members with floor surface, is continually being innovated to minimise cost and construction time and maximise buildability, safety and sustainability.

The infographic below provides an indication of the types of structural systems utilised and current and potential innovations. For more information on innovation, refer to our focus area on steel innovation and visit the ASI Steel Innovation Portal.

The Australian Fabricator Directory (PDF) contains ready guidance for constructors, builders, quantity surveyors and other construction professionals on the capability and capacity of Australian structural steelwork fabricators who have demonstrated local production and project management skills in multi-level buildings.

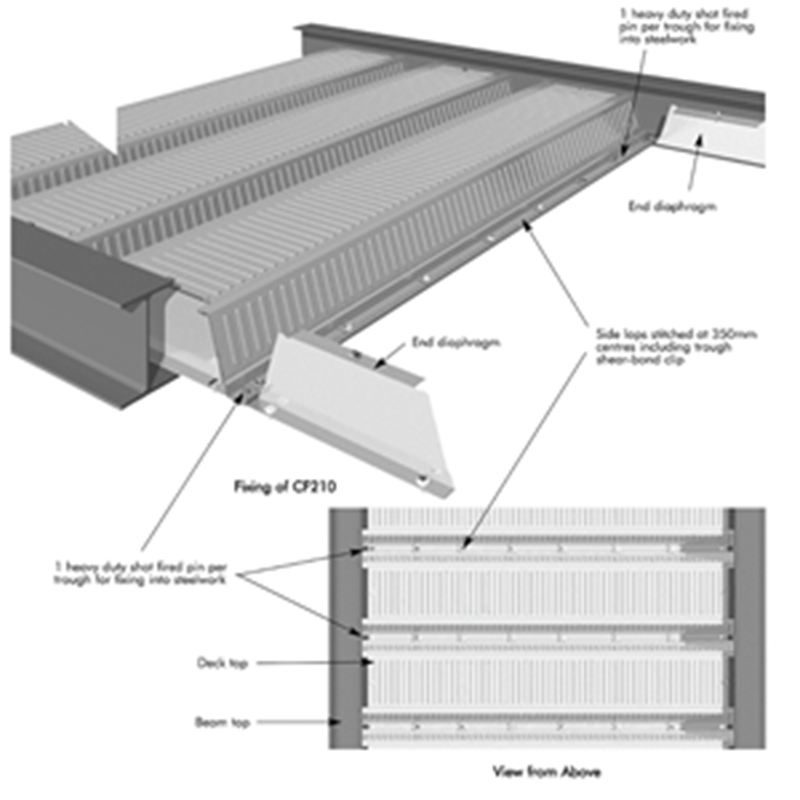

Structural steel is increasingly being considered and utilised for the primary gravity-supporting structural systems in multi-level residential construction. A particular innovation introduced into the market recently is the configuration of the floor framing system, placing the primary steel floor framing beams within the depth of the composite slab, utilising deep trapezoidal steel decking supported off the bottom flange of the steel beams.

Structural steel is increasingly being considered and utilised for the primary gravity-supporting structural systems in multi-level residential construction. A particular innovation introduced into the market recently is the configuration of the floor framing system, placing the primary steel floor framing beams within the depth of the composite slab, utilising deep trapezoidal steel decking supported off the bottom flange of the steel beams.

This significantly reduces the overall depth of the structural floor, thereby allowing more floors within the building height limitations imposed by the relevant authority. Combined with the advantages of steel for speedy construction, safety and constructability on tight CBD work sites, this innovation alone has provided the steel solution credible performance advantages over competing structural solutions.

A preeminent example of this is the Meriton residential tower project in North Sydney, engineered by enstruct. Particular technical details of the trapezoidal deck support system are illustrated below.

Above images) Courtesy enstruct.

The structural benefits claimed for the Meriton building include:

CASE STUDIES