In an industry-first collaboration, the Australian Steel Institute (ASI) has coordinated a working group to establish a realistic standard for sustainability in paint within the steel industry.

The working group of paint manufacturers, building industry representatives and members of the Australasian Corrosion Association (ACA) ran various scenarios to determine what was achievable for fabricators, what is in their zone of responsibility and what could be auditable by the ASI’s Steel Sustainability Australia (SSA) scheme.

A final new SSA Credit 3.1 Paints and Coatings (linked below) was endorsed by the GBCA, who also published an associated FAQ F-00332 What can be excluded from the scope of Minimum Expectations in the Exposure to Toxins credit from Green Star Buildings.

The working group comprised paint manufacturers, building industry representatives and members of the Australasian Corrosion Association (ACA).

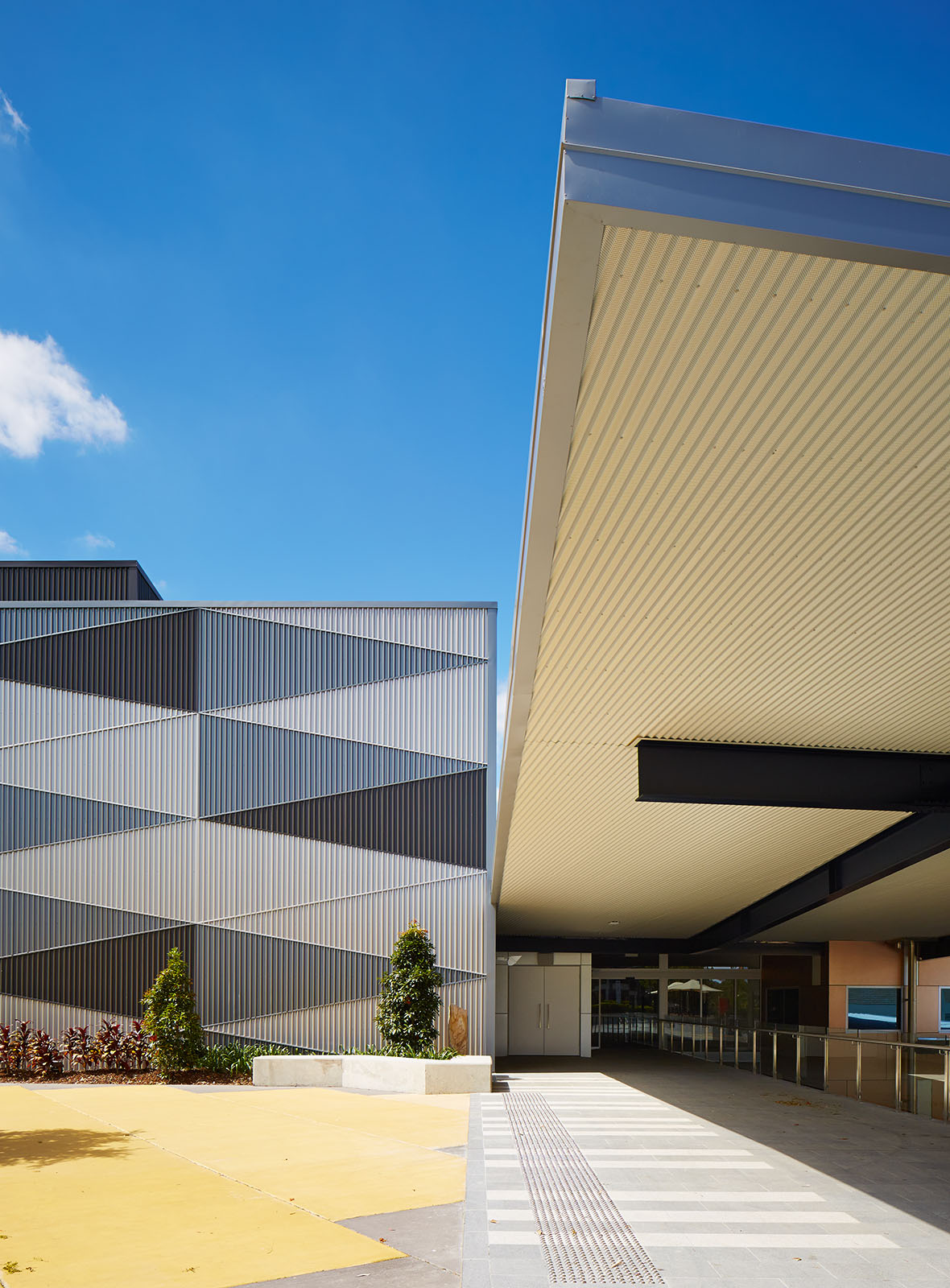

St Peters Lutheran College Performing Arts Centre, photographer Scott Burrows

Working group members had lengthy discussions over a period of four months. Topics included the sustainability and circularity of steel, the importance of anti-corrosion paint to the longevity and durability of steel, the volatile organic compound (VOC) levels in solvent based paint and the decay times of VOCs associated with the drying time of paint.

An important step was acknowledging where the paint industry is at in terms of measuring and reporting of VOC levels and understanding the complexities of measuring VOC decay times. Dulux and AkzoNobel provided technical input, which was invaluable in gaining intelligence in paint chemistry and determining what’s possible for steel fabricators. Built Australia provided input into the site practicalities of what is achievable in measuring VOCs on building sites and providing assurance to project teams that VOC limits are met.

The challenge was to find a solution whereby fabricators could demonstrate paint was applied to steel products in a safe manner to reduce impact to their health and wellbeing and retain compliance with VOC limits set by the Green Building Council of Australia (GBCA) within the construction of a building.

Bringing together representatives from each of these industries led to a successful outcome and offered valuable insights for the GBCA’s Responsible Products Framework. Launched in 2020 the Green Star Buildings rating tool relies on initiatives such as SSA to assess and certify best practice sustainable businesses and products. Developed closely with GBCA and key stakeholders in the steel supply chain, the SSA scheme was launched in 2023. It serves as a leading platform for downstream Australian steel suppliers - including fabricators, roll formers and reinforcing businesses - to showcase their commitment to sustainability within the building industry. Whilst SSA is a stand-alone program, certification also results in Responsible Product Values which translate to Green Star credits under the GBCA rating tools.

ASI’s ability to unite key stakeholders for positive outcomes is one of the benefits of ASI membership and the collaborate approach of this working group is a testament of effective teamwork in action for the benefit of the steel industry.

For more information on ASI’s SSA scheme, visit the website or email ssa@steel.org.au.