Cold-formed light gauge steel members and profiled sheeting are produced from steel strip usually supplied in coil form from the steel mill.

In Australia, Bluescope Steel Limited is the predominant manufacturer of steel strip. Both hot-rolled coil (HRC) and cold-rolled coil (CRC) are produced for different markets and applications.

Cold-rolled coil is usually supplied in the range 3.5mm to 0.3mm in thickness and is generally metal coated, either galvanized or ZINCALUME®. Hot-rolled coil is generally supplied in thicknesses from 1.5mm upwards. Additional coating processes, such as painting, are then applied.

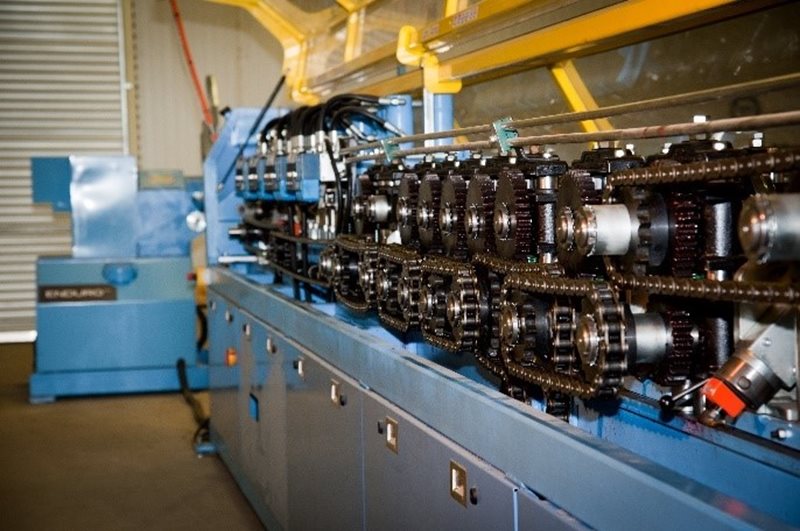

The uncoated or coated coils of steel strip begin the process of being turned into cold-formed steel sections and profile sheet with being uncoiled, slit into appropriate widths and then cold-formed into the required final profile shape, usually by a continuous process passing through a number of roll stages to form the final product shape. These processes are undertaken by roll formers, who may work as contract businesses tooling up and producing a range of specialist section shapes for various clients, or at dedicated facilities working in-house with manufacturers of specific product lines for purlins, girts, structural framing, profiled sheeting or metal decking.

.jpg?variant=FullWidth)

.jpg?variant=HalfWidth)

For certain product types it is logistically easier and more economical to roll the product on site and then directly install onto the final structure. In this case, the roll forming machinery is usually truck mounted and brought to site.

ARAMAX roofing is rolled on site. Courtesy Bay & Coast Metal Roofing.