Architecturally exposed structural steel (AESS) is a mixture of art, science and know-how. It can express the structural integrity of a building in a striking way and put the structural system at the forefront aesthetically. AESS can also combine form and function, expressing a playful intent while at the same time functioning as a primary load carrying system.

Increasingly, buildings are showcasing AESS to provide a signature identity, whether that is up close and personal in the entrance lobby or externally as a statement to establish the architectural presence and strength of the building. In these multifarious roles, steel can be viewed from a range of distances and must respond accordingly to level-of-detail considerations, balancing the degree of finish and detailing against cost and practicality.

The ASI has developed and provided a range of support material for architects to enable fit-for-purpose specification of the appropriate AESS requirements.

.png?variant=HalfWidth)

Delivering a successful AESS structure is not difficult, provided that clear communication about intent is maintained among the architect, engineer and fabricator. AESS has significantly higher requirements for the form, fit and finish for fabrication, erection and coatings than regular structural steelwork. These must be taken into account throughout the development process. Architects therefore become part of a triangle of communication in their documentation with the engineer and the fabricator, which will affect the way engineers design connections and the way fabricators finish connections, as well as the cost.

This interactive design process is very different from the more linear process associated with ‘standard’ structural steel that is hidden from view and where the architect can often step back from detailed involvement.

Communication can be improved by considering the following points:

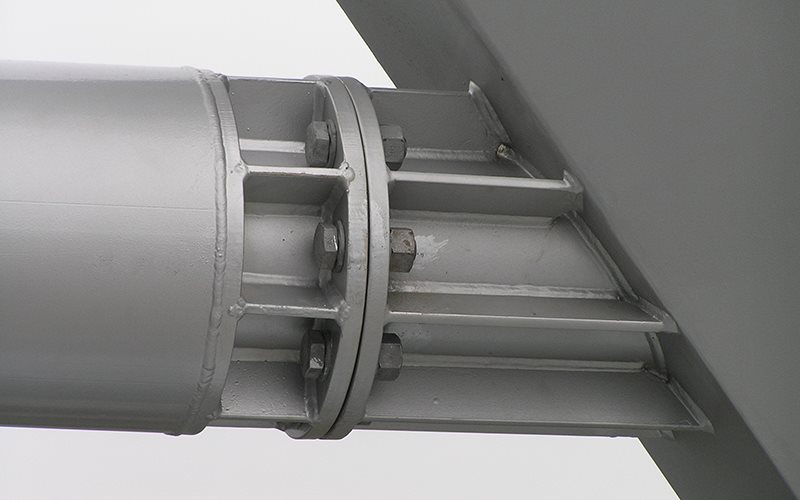

Connections that are to be exposed must be designed differently than those that are concealed. Decisions relating to the use of welded versus bolted connections must be informed by the overall requirements for the design of the structural system.

Integrating connections with the architectural intent can be improved by considering the following points:

Cost estimates from fabricators can vary markedly depending both on the type and extent of AESS treatment and also on their understanding and comfort level. Be specific and communicate early. Understand the impact of viewing distance and use as this may allow simpler detailing and other finishing options.

The following considerations will help minimise unnecessary costs: