Steel provides a particularly elegant and cost-effective solution for building structures. Steel structures deliver value, both in the initial build and over the full life cycle of the operating building.

Among the many benefits offered by the use of steel in construction are its:

.jpg?variant=HalfWidth)

Steel delivers significant value in a number of areas, including the following:

Steel use reduces the number of workers on site considerably (as a rule of thumb, steel construction needs approximately 10–20% of the labour needed for concrete construction). This considerably reduces the accident liability rate for the builder

Accurate and efficient offsite construction reduces the amount of handling required

Preassembled steel construction packages can be lifted straight from truck to building in construction sequence

Reduces the amount of temporary work required

Safety now rates first in the criteria of importance in the building industry and has significant cost implications.

Off-site steel fabrication means quality issues are sorted out offsite, thereby saving time

Steel construction is universally recognised as significantly faster than concrete construction

Improved speed markedly affects preliminary costs

Earlier construction provides earlier completion and payback commencement

Staff are released quickly for the next project.

Every batch of steel produced is certified and traceable

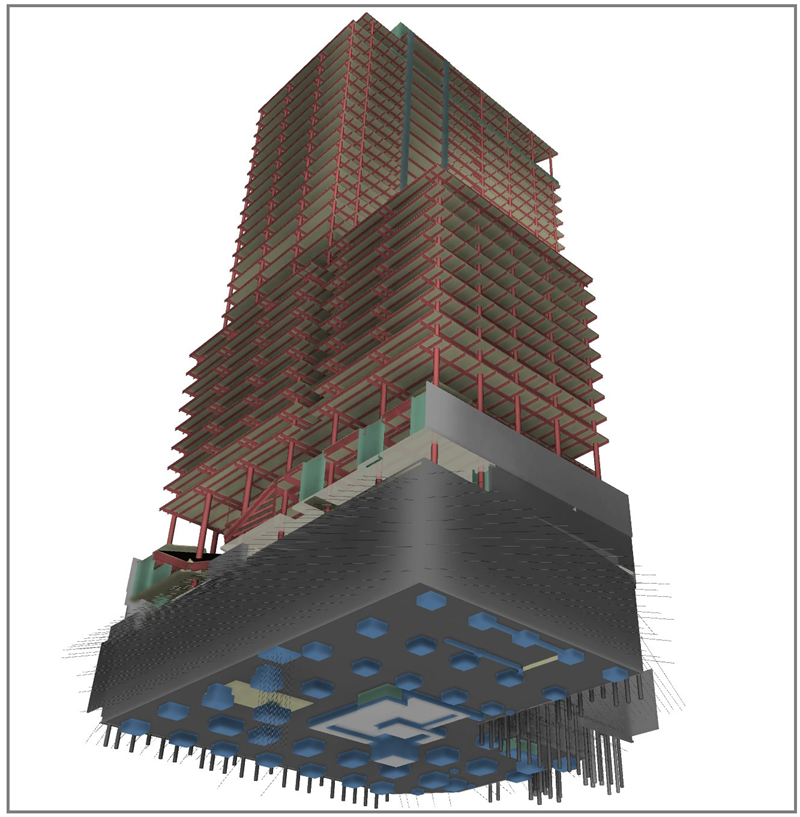

Fabrication is driven by 3D modelling and numerically controlled fabrication equipment

Steel provides the surest guarantee of quality construction.

Steel is structurally efficient and buildings are considerably lighter as a result

Foundations are lighter and cheaper relative to concrete

Just-in-time deliveries can be sequenced and synchronised with the construction program

Steel is fabricated in controlled conditions with little waste.

More than 95% of all structural steel is recovered and reused or recycled. Steel by weight is the most recycled material in the world without degradation or loss of quality

Steel buildings inherently lend themselves to addition and modification easily and quickly

Environmental Sustainability Charter members have an auditable environmental management scheme rewarded with a Green Star point.

Steel construction worldwide has undergone dramatic efficiency gains due to technology (e.g. Computer Numerically Controlled [CNC] processing and Building Information Modelling [BIM])

The steel economy is global and productivity gains and innovation are shared as extensive research and development becomes available.

Significant savings can be made through reduced waste reduction compared to concrete construction (one project recorded $200,000 in savings)

There are considerable savings in freight through not having to use and remove formwork

Use of steel means significantly fewer truck movements.

Provision of large penetrations in steel construction to allow future use requirements

Ability to cut floor penetrations in steel to allow for stair access at a later stage

Ease of reinforcement of steel columns to provide for height increases at a later stage

Ease of additions to the construction – e.g. for shopping centre extensions, with minimum disruption to tenants.

Overcomes congested and hard-to-access sites

Reduces noise and dust generation during construction, with positive outcomes for the local neighbourhood

High-quality, safer and quicker construction.

Follow the links below for detailed information on the following building types:

Buildings using cold-formed light-gauge construction

The ASI has undertaken a body of work to provide some clarity on the costs and cost drivers for multi-level construction in steel. Resources relating to costs and cost drivers can be found here.

The most effective approach to reducing steelwork construction costs is through pragmatic value engineering. Steelwork responds exceedingly well to considered approaches to rationalisation, with the potential to reduce costs in all phases of the building supply process.

CASE STUDIES