Guidance on material compliance

Our design Standards provide guidance on requirements for material compliance to suit the performance intent of the Standards:

From AS 4100:

Clause 2.2.2 Acceptance of steel

Requires test reports or test certificates be provided by the manufacturer or by an independent laboratory accredited by signatories to the International Laboratory Accreditation Corporation (Mutual Recognition Arrangement) (ILAC MRA) or the Asia Pacific Laboratory Accreditation Cooperation (APLAC) on behalf of the manufacturer. Where there is a dispute as to the compliance of the steel, reference testing shall be carried out by independent laboratories accredited under ILAC MRA or APLAC.

The veracity of the testing laboratories must be established. There have been documented cases of laboratories undertaking testing they are not competent for.

Clause 2.2.3 Unidentified steel

"If unidentified steel is used ... unless a full test in accordance with AS 1391 is made, the yield strength of the steel used in design shall be taken as not exceeding 170 MPa, and the tensile strength used in design shall be taken as not exceeding 300 MPa."

If the steel cannot be properly identified according to the requirements of AS 4100, this very significant reduction in strength must be utilised in design. For most project scenarios, this strength reduction will be untenable as a design requirement, particularly if the design and sourcing of product has already been undertaken.

From AS/NZS 4600:

Clause 1.5.1.5 Acceptance of steels

The marking of steels shall be as specified in the appropriate Standard.

Clause 1.5.1.6 Unidentified steel

Similar requirement to Clause 2.2.3 in AS 4100 above.

From AS/NZS 5100.6:

Clause 2.2.3 Unidentified steel

"Where steel does not satisfy the requirements of Clause 2.2.2, it shall be classed as unidentified steel. Unidentified steel shall not be used."

This clause is more onerous than the similar Clause 2.2.3 in AS 4100. No strength reduction is allowed, reflecting the importance of steel veracity to bridge performance.

Material Standards

The material Standards (AS/NZS 1163, AS/NZS 3678, AS/NZS 3679.1, AS/NZS 3679.1) provide consistent guidance across all four Standards, namely:

Clause 11.1 Identification: itemises the range of requirements for the identification marks to be provided on the steel product. Products not marked with the provisions are non-compliant with the Standard.

Clause 11.2 Test and inspection certificates: outlines the requirements for test and inspection certificates that shall be available to the purchaser for each batch produced. Tests shall be undertaken by laboratories accredited by signatories to ILAC MRA. Minimum sampling and testing procedures shall conform to Appendix B.

Appendix B Product Conformity: is a normative appendix that outlines the scope for initial type testing (ITT) and factory production control (FPC) to be demonstrated by the manufacturer or supplier. Minimum sampling and testing frequency plans are documented. The product conformity requirements are intended to enable conformity assessment to be made by a manufacturer or supplier (first party), a user or purchaser (second party) or an independent body (third party).

Fabrication Standard:

From AS/NZS 5131:

Clause 13.3.7 Nonconforming steel or components

Requires that if documentation is inadequate or incomplete such that compliance cannot be adequately established, the steel material or component shall be treated as unidentified steel in terms of AS 4100, AS/NZS 4600 and AS/NZS 5100.6. If testing of nonconforming material or components is undertaken, the results shall be in accordance with Clause 13.3.8.

Clause 13.3.8 Testing of nonconforming steel or components

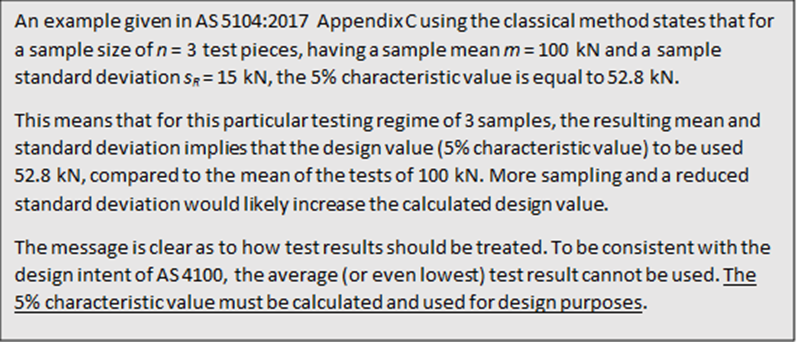

"The type of testing shall be consistent with the type of testing specified in the relevant product Standard cited in Clause 5.3, and shall be sufficient to establish a proper statistical basis. Single or limited test results shall not be acceptable. Appropriate statistical processes shall be applied to multiple samples in order to establish confidence in the properties of the product."

This clause makes it very clear that a proper regime of testing needs to be undertaken (refer to the following section).

Testing of steel

Where testing of steel is required, the procedure for and extent of sampling must be considered and carefully managed to ensure the intent of the Standards is maintained. A proper statistical process should be applied consistent with the intent of the Standards.

Clause C2.1 of the Commentary to AS 4100 speaks to the yield stress and tensile strength used in design and states, in part:

"Variations in the yield stress and tensile strength, which occur during manufacture, are accounted for in the derivation of the capacity factor (Ø) (see Clause C3.4). Because of this fact, the actual values of yield stress or tensile strength recorded on mill test reports or certificates cannot be used for design. The values used in Table 2.1 should not be exceeded in design or else the derived capacity factors of Table 3.4 are rendered invalid.”

This makes the point that actual values of yield stress and tensile strength as shown on test certificates are not appropriate to be used for design purposes.

ASNZS 5131 requires that, with regard to testing of nonconforming steel or products, “appropriate statistical processes shall be applied to multiple samples in order to establish confidence in the properties of the product”. This clearly establishes that single or limited tests are not appropriate.

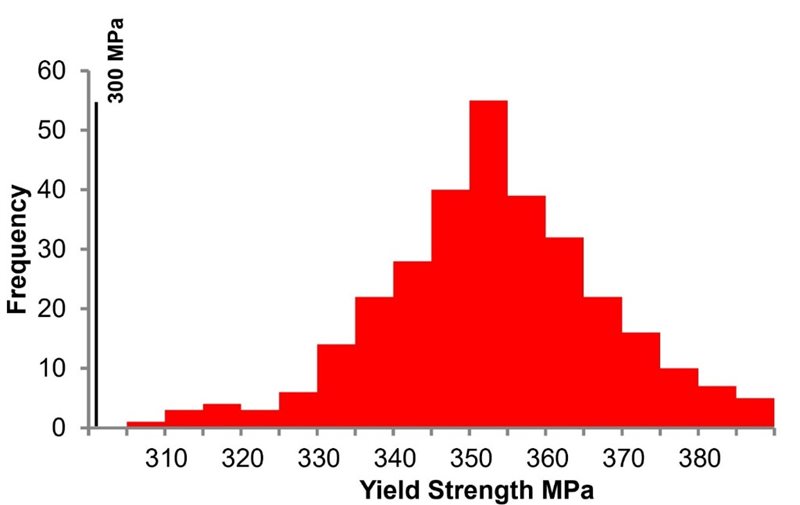

When undertaken as part of Factory Production Control (FPC) as part of the manufacturing process, tests of the steel are undertaken at regular intervals and build up a statistical profile of the manufacturing performance of the steel plant as well as the particular properties of the steel batches produced. For example, as would be expected, there is a variation (often a normal distribution but depends on the property measured) around a mean value of the yield stress for each grade of material produced, as indicated in the figure below:

.jpg?variant=HalfWidth)